How are office chairs made? The full process of producing a complete product requires multiple stages. They include careful design, material options, part manufacturing, consideration of quality, customization, ergonomics, assembly, and final testing.

Keep reading this article to learn more about each step in making a product with detailed descriptions and attention.

How are office chairs manufactured?

The complete process of making them includes six main stages: Research and design, material selection, upholstery production, component production, assembly, and quality inspection.

Research and design the office chair

An industrial designer and engineer will collaborate to design the concept, generate the 3D model, and prototype the ideal product version. This collaboration will help share the expertise in improving function and aesthetics. Also, user feedback is essential at this stage to help refine the item design.

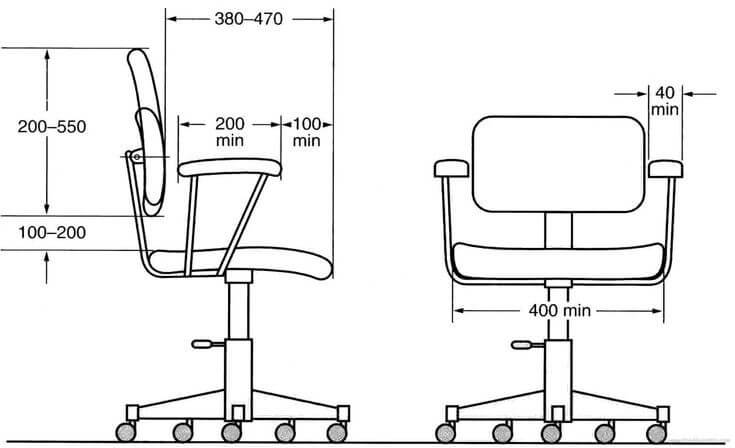

In this stage, ergonomics calls for complete attention, concentrating on developing items harmoniously with the user’s body. Doing so ensures that it does not cause pain or discomfort even after long hours of use. Producers will research human posture, anatomy, and movement to manufacture adaptable and supportive products.

Choose the right material

Choosing suitable materials decides the item’s comfort, durability, and quality. Many prevalent materials are available, including fabric, leather, metal, mesh, plastic, and foam.

Leather, for instance, is an excellent material for comfort and luxury, but it can need more frequent maintenance. Meanwhile, the mesh is highly regarded for its relaxation and breathability, ideal for hot weather.

Balancing materials’ quality and comfort with their environmental effects is essential. Plus, sustainability is a critical factor when picking materials. Producers often look for environmentally friendly alternatives, including fabric or recycled plastic.

Make the upholstery

An employee first smoothes the right leather type on the table. Then cut out the pattern using a cardboard template. Workers ensure the necessary leather size for the chair and trim it carefully to minimize waste. You can see that cutting leather with the same large pieces will give upholstery consistent texture and color.

Another employee will prepare leather samples and cut the foam cushion for the back of the char. Next, workers make narrow canals or channels by cutting slits into foams. Then draw a line with chalk on the corresponding leather.

Another employee makes slits in the leather using chalk and gathers them together to create a ribbed pattern when sewing the lining. Then, sew the padding flat onto other pattern areas. When the leather upholstery is complete, employees will wrap the foam structure by adding a chipboard panel and covering it using upholstery.

Read more: How To Reupholster An Office Chair

Component production

Part manufacturing is essential during the production stage. Crafting will turn into the desired shapes from the shaping and molding of materials.

It also involves cutting the material into the size or shape that matches the requirement of the item. Both processes ask for advanced supportive machinery to increase efficiency and precision.

Cushioning contributes to furniture comfort, and high-quality foam is helpful for cushioning with its durability and comfort. The foam requires precise shaping and contouring to the design. Foam thickness and density are also crucial factors in giving comfort to you.

Assembly phase

This stage will start with assembling the parts, including the backrest attachment and seat-to-frame attachment, ensuring firm security.

Finally, attach some other parts, such as armrests and casters. This stage helps the office chair be mobile, functional, and ready to use.

Quality management and the final inspection

Making a perfect office chair also necessitates thorough quality control to help ensure the product’s stability, durability, and safety. This stage will entail material, strength, and weight testing.

Besides, the inspection step will test the item’s ergonomic support and comfort. A chair that has passed these inspections guarantees a comfortable seating position and supports movement and posture.

Read more: How To Choose An Office Chair

Conclusion

How are office chairs made? The above is a complete process to help you know this. The first step is to research and design the desired item. Next, choosing a suitable material is essential to produce a good-quality chair. Besides, from the upholstery, part production to the assembly stage requires a rigorous process to make the best product with ergonomic support and comfort.

If you give more information, please watch this video below:

FAQ